GE Oil & Gas has replaced-in-kind a gas turbine at a Texas Gas Transmission, LLC pipeline compression station in Mississippi.

FLORENCE, ITALY [WorldofCogeneration.com]

GE Oil & Gas has replaced-in-kind a gas turbine at a Texas Gas Transmission, LLC pipeline compression station in Mississippi, using advanced technology designed to revitalize and recover performance with improved efficiency.

Commissioned in 1969, the original GE Frame 32H gas turbine had operated successfully at the Lake Cormorant compression station for more than 200,000 hours due to a well-structured program of repair and maintenance. However, the next scheduled outage brought an unknown repair scope due to end of life issues for turbine discs, buckets and other hot gas path components.

When the company decided to make a long-term investment that would revitalize the original package, Texas Gas again turned to GE, this time to upgrade the technology in a project valued at more than $4 million, designed to leverage technologies from GE’s advanced fleet of Frame 5, 6 and 7 gas turbines.

GE incorporated new design features into a newly manufactured replacement Frame 32J machine for the Lake Cormorant station, increasing efficiency by 2%. The new unit is currently in full-speed, full-load operation and Texas Gas has ordered a second unit, scheduled for October 2010 delivery.

Bill Nunn, manager compression support, Texas Gas said: “Knowing that several of the hot gas path components were reaching the end of their design life, we began evaluating our options to restore the existing unit to its original performance. GE was able to offer a new gas turbine tube that not only incorporated their advanced technology, but also proved to be an economically viable project.”

Jeff Nagel, vice president global services, GE Oil & Gas said: “It’s a testimony to the reliability and endurance of our engineering that the original Frame 32H-J had clocked over 200,000 hours of performance. To meet Texas Gas’ requirements, we delivered a unique, tailored solution, injecting our latest, proven technologies into the new Frame 3 unit. This solutions-based approach has enabled Texas Gas to improve the maintenance cycle and restore performance at the station by increasing reliability without compromising on quality.”

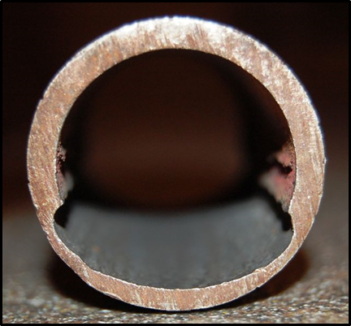

Equipment for the replacement unit was supplied from GE’s Florence, Italy manufacturing plant and included a new gas turbine tube comprised of a compressor discharge case, turbine case, low-pressure and high-pressure shafts with buckets, compressor rotor and stator blades and additional parts.

Texas Gas Transmission operates a long-haul interstate natural gas pipeline that moves gas from Gulf of Mexico supply areas to Midwestern and Eastern U.S. gas markets. Texas Gas is a wholly owned subsidiary of Boardwalk Pipeline Partners, LP of Houston, Texas.