Location: Brandon, Queensland

Grid-connected, distributed

The site

Pioneer Mill at Brandon was an ideal location for CSR’s second major cogeneration project. The site is centrally located in the Burdekin sugar growing region, allowing natural transport effi ciencies to be taken advantage of, and the existing facilities were well suited to refurbishment and upgrade. The mill also had a large excess of available fuel and adequate storage area.

Technology

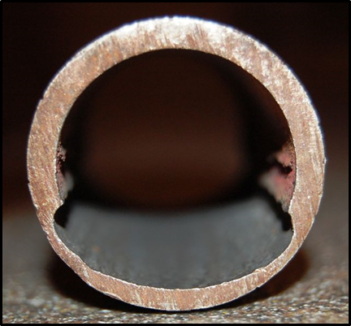

The plant incorporates certain technology new to the sugar industry that allows the mill to operate under normal sugar operations whilst exporting electricity in a cleaner and more efficient way than in the past. This includes the installation of horizontal wet arrestors that save space and reduce stack emissions, a high pressure 65 Bar(a) boiler and a closed water circuit condensing turbine. Ash waste volumes are reduced by using a dry ash system and a neutralisation tank reduces environmental risk. The plant is the first electric driven mill in Australia. During the “non-crush” period the plant operates as an independent and selfsufficient power plant using the condensing turbine set only.

Energy purchase and supply

The plant is expected to produce 260 GWh of electricity per annum, resulting in greenhouse emissions reductions of 260,000 tonnes per annum (equivalent to removing 52,558 cars from the road each year). Power generated is sold to Ergon Energy under long-term agreement. The generator is registered as a non-scheduled, non-market generator and

operates intermittently. Fuel for the plant is supplied by CSR’s normal sugar operations in the region. The plant will allow bagasse that would normally be burnt less effectively at other sites to be transformed into energy at greater efficiencies. The project is accredited under the Mandatory Renewable Energy Scheme.

Heat recovery and use

Greater heat effi ciency was a major goal of the project and was achieved largely by the electrification of the milling tandem, removal of smaller steam turbines around the boilers and new evaporator designs. During cogeneration operations steam from the backpressure turbine is used for sugar processing. However, the steam from the condensing turbine feeds

to the high pressure boiler on a closed circuit and heat is removed via a 70 MW evaporative cooling tower.

| Owner: |

| CSR Sugar |

| Capacity: |

| 68 MW |

| Location: |

| Brandon, via Ayr (90 km from Townsville), QLD |

| Commissioned: |

| September 2005 |

| Capital Cost: |

| $160 million |

| Construction Contractor: |

| United Group Infrastructure |

| Operator: |

| CSR Sugar |