The waste heat from gas engines can be used for drying processes, such as in the ceramics, brickworks and animal feed industries. It can also be used for slurry drying, resulting in a marketable fertilizer.

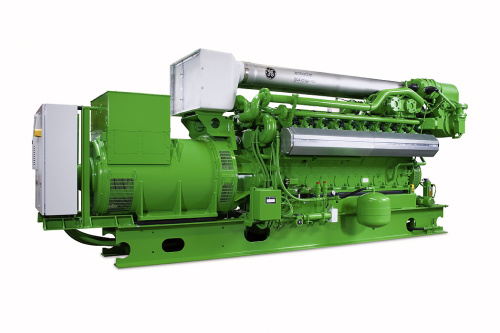

Growing ecological awareness, coupled with the knowledge that fossil sources of primary energy are limited, compels us to make more economical use of our existing sources of energy. Combined heat and power (CHP) plants generate electricity and heat locally where they are needed. They offer maximum efficiency in the conversion of energy and comply with the most stringent emissions standards.

Cogeneration Systems

GE’s Jenbacher gas engines are ideally suited for cogeneration plants. With optimized electrical efficiency, our cogeneration plants provide optimal integration of all available kinds of heat from the engine.

Trigeneration

Absorption equipment uses the waste heat from a CHP module as energy for cooling purposes.

CO2 Fertilization

The carbon dioxide from the exhaust of a gas engine can be used for the fertilization of greenhouses.

Hot Water Production

The waste heat from CHP plant operation can be used to base heat hot water.

Steam Generation

The waste heat from CHP plants can be used to generate steam for industrial operations, hospitals and food processing operations.

Drying Processes

The waste heat from gas engines can be used for drying processes, such as in the ceramics, brickworks and animal feed industries. It can also be used for slurry drying, resulting in a marketable fertilizer.