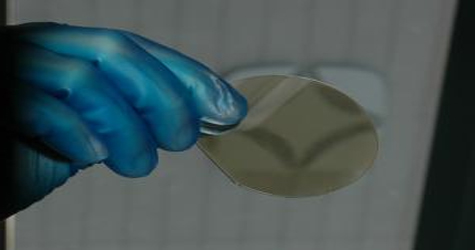

The new Gallium Nitride products are based on an innovative n-type material which has a higher transparency and a lower carrier concentration and should have additional advantages for the production of photovoltaic applications.

During the last twelve years Ammono has been developing a technology allowing the manufacture of GaN wafers with carrier concentrations between 2×1017 and 2×1020 cm-3. Today the standard n-type product has a carrier concentration of 1019cm-3.

Responding to market needs, Ammono is introducing new products based on an innovative n-type material which has a higher transparency and a lower carrier concentration of 3x1017cm-3. The firm believes its new ammonothermal GaN substrates present additional advantages for the production of photovoltaic applications among others.

The dislocation density in this material remains at a level of 5×104 cm-2 which Ammono says is currently the best commercially available. Initially Ammono will offer high transparency substrates in form factors of 10 mm x 10 mm square wafers and circular 1” wafers. In 2012 besides its standard 2” n-type AMMONO-GaN substrate, the company aims to introduce a 2” product based on this new high-transparency material.