A startup with a secret recipe for printing cheap solar cells on aluminum foil debuted today, in what could end up a milestone for the industry

Nanosolar’s technology consists of sandwiches of copper, indium, gallium and selenide (CIGS) that are 100 times thinner than the silicon solar cells that dominate the solar photovoltaics market. Its potential convinced Google founders Sergey Brin and Larry Page to back the company as angel investors in its early days.

Two big announcements marked its coming out party: The company has $4 billion in contracts and can make money selling its products for $1 per watt of a panel’s capacity. That’s cheap enough to compete with fossil fuels in markets across the world.

Specifically, the company’s management thinks it can help utilities avoid the difficulties of getting big coal and nuclear power plants built by offering the option to build small solar farms they can set up close to cities.

“Cost-efficient solar panels such as ours can be deployed in 2- to 20-megawatt municipal solar power plants that feed peak power directly into the local distribution without requiring the expense of transmission and with a plant deployment time as short as six months,” said Nanosolar CEO Martin Roscheisen in an e-mail to Wired.com. “Coal or nuclear can’t do that, can’t do it as cost efficient and can’t do it as rapidly deployable.”

Thin-film solar has been a major focus of U.S. alternative energy research and development efforts since the early 1980s because it was seen as a true “breakthrough” solar technology. Silicon cells are easy to manufacture, dependable and efficient, but some researchers viewed them as inherently limited. As they are currently produced, they require a lot more silicon than thin-film solar cells. They might reach efficiency levels of over 40 percent, but they’d never compete with fossil fuel energy sources, even with carbon taxes.

Thin-film solar was different. On the one hand, it was definitely harder to make efficient cells. However, it allowed researchers to dream of printing semiconducting chemicals onto a metal sheet and having it convert photons into electricity. Thin-film cells seemed like they’d be perfect for the applications researchers imagined like “solar shingles” for building-integrated solar installations.

Thin film was promoted as the technology that would bring photovoltaics to the masses at prices competitive with fossil fuels.

The National Renewable Energy Laboratory worked steadily on thin films throughout the 1990s, but no technology seemed to work well outside the lab. It turned out to be really difficult to actually manufacture thin-film solar cells.

Then First Solar exploded onto the solar scene in 2005 with a cadmium-telluride thin-film cell. Their manufacturing costs dropped rapidly and soon they had billions of dollars in contracts, largely with utilities. Yesterday, they signed a two-gigawatt deal with Chinese officials. Now, investors value the company higher than American, Delta, and United Airlines combined. First Solar has become the bar and the target for Nanosolar, and the dozens of other thin-film market hopefuls.

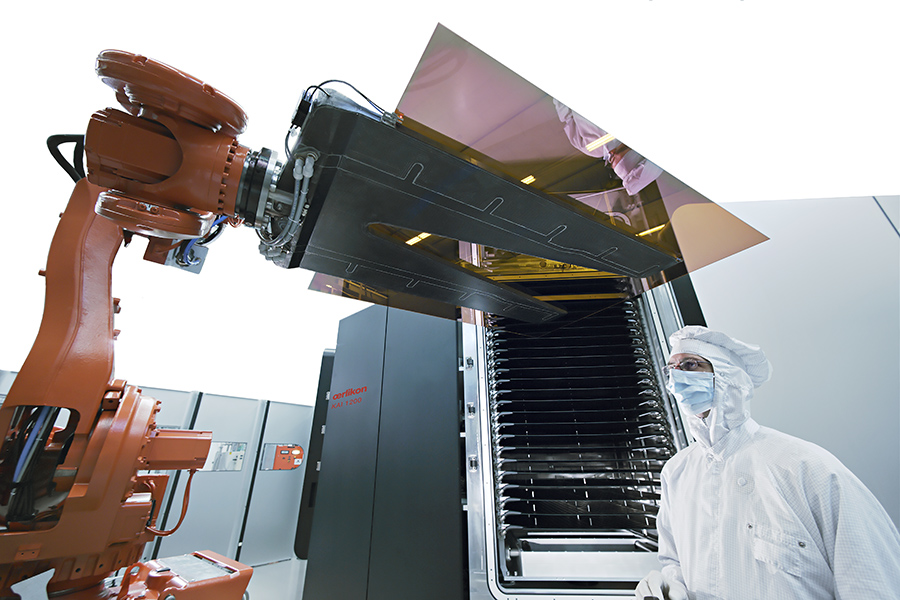

What could set Nanosolar apart is the way the company actually gets its semiconductors to stick to the metal foil. Most companies use various techniques executed under vacuum conditions; Nanosolar prints its solar cells.

“What separates them from the rest of the companies is that they have developed a process to make CIGS cells which involves non-vacuum technology,” said Miguel Contreras, a thin-film solar researcher at the National Renewable Energy Laboratory. “This is a very generic description, but what I’m pointing out is that by having a wet chemistry process, they are able to save quite a bit of money in terms of capital equipment.”

The base for their cells — the aluminum foil — is plentiful and cheap, which the company says has cost and manufacturing advantages.

Earlier this year, First Solar claimed it started manufacturing solar cells for less than $1 per watt. Nanosolar says it can go cheaper. They also took aim at First Solar in a recent whitepaper (.pdf) for utilities, claiming their “balance-of-system costs” (all the other stuff beyond the solar cells themselves) will be lower.

It’s big talk for a company that hasn’t really entered commercial production, but Nanosolar has a half a billion dollars in venture funding and some bleeding-edge technology. Beyond the contracts they’ve won, they announced that NREL testing found their cells to be the most efficient printed solar cell on record at 16.4 percent.

Even though the competition among solar companies is heating up, there is plenty of room for multiple players in the expanding renewable energy markets. Competition can drive innovation and cost reductions, too, which would be good news for solar energy advocates. After major cost drops in the early ’90s, the average solar module’s cost hasn’t been declining very quickly.

If companies like First Solar and Nanosolar continue to grow, they will drive that average price closer to competing with fossil fuels. First Solar will be producing about a gigawatt of panels this year. Nanosolar’s production is tiny, by comparison. They have a 640-megawatt facility, and are ramping up production from their current megawatt per month of production. Scaling up can be difficult with PV technologies, but Roscheisen was confident.

“There are manufacturability issues with CIGS but you wouldn’t hit a million cells a month unless you have worked out these,” he said. “This is why our manufacturing people have considered going from 0 output to 1 megawatt a month in output as more challenging than scaling from 1 megawatt to 100 megawatts or more.”