Associated gas – gas produced along with oil – and stranded gas located in fields far from existing pipelines and infrastructure are potentially valuable resources that are often wasted.

Stranded gas fields are sometimes left undeveloped, and associated gas is often disposed of by the environmentally damaging practice of flaring because there is no practical and economical method available to transport the gas to market.

In a talk to be given on Tuesday, 17 September 2013 at the 5th International Gas Technology Conference (IGCT), in Moscow, Russia, Neville Hargreaves, Business Development Director of Velocys will outline the benefits of Velocys smaller scale gas-to-liquids (GTL) plants. The technology, which is based on the use of microchannel Fischer-Tropsch (FT) reactors combined with a highly productive, selective and stable FT catalyst, provides an economical and efficient way of capturing the value of associated and stranded gas.

The presentation, entitled GTL – an economic solution for distributed gas, is scheduled to begin at 9:05 and will form part of a morning session devoted to GTL.

Neville Hargreaves, Business Development Director, Velocys said:

“Our smaller scale GTL technology offers an effective way to reduce carbon dioxide emissions from flaring and to monetise associated and stranded gas. It provides a practical way to unlock constrained oil production and to increase revenues and reserves using existing transport infrastructure, and can also be used to produce diesel for local demand.”

Smaller scale GTL

Conventional GTL technology is only economically viable for plants producing around 30,000 barrels per day (bpd) or more. Only about 6% of the world’s known gas fields are large enough to sustain a GTL plant of that size. In contrast, the smaller scale GTL plants being developed by Oxford Catalysts Group and marketed under the brand name Velocys are based on the use of microchannel Fischer-Tropsch (FT) reactors and are designed to operate efficiently and economically when producing between 1,000 and 15,000 bpd of liquid fuels. GTL at this scale could unlock up to 50% of the remaining fields that conventional GTL cannot economically exploit. In total, smaller scale GTL could produce as much as 25 million barrels per day of synthetic fuels annually, worth hundreds of billions of dollars.

Smaller scale GTL plants provide a cost-effective way to take advantage of undervalued resources, such as shale gas and stranded gas located far from existing pipeline infrastructure and markets. The technology provides an economic alternative to the large-scale flaring of associated gas, which is an on-going environmental concern.

Velocys smaller scale GTL plants are built in a modular fashion and can be scaled up to match the gas resource. Investment can be phased. The plants are fabricated mainly in a factory environment, with each unit designed to fit into a standard-sized shipping container for ease of transport. Because roughly 70% of the plant is complete before the modules are shipped, the time and cost needed to construct the plant on site is greatly reduced. This approach allows good control of the capital cost and engineering quality, and a faster project schedule.

Microchannel Fischer-Tropsch (FT) reactors

Microchannel technology is a developing field of chemical processing that intensifies chemical reactions. It enables lower cost, smaller and more productive processes by improving the heat and mass transfer performance and reducing the dimensions of the reactor systems. Mass and heat transfer limitations reduce the efficiency of the conventional large FT reactors. The use of microchannel technology makes it possible to overcome these limitations and to intensify the chemical reactions, enabling them to occur at significantly higher rates than in conventional systems.

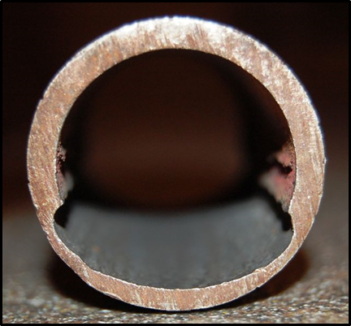

Microchannel FT reactors are compact reactors containing thousands of channels with characteristic dimensions in the millimetre range. The FT process is highly exothermic, or heat generating. In microchannel FT reactors process channels, filled with catalyst, are interleaved with water-filled coolant channels. The small-sized channels dissipate heat more quickly than conventional fixed-bed reactors with relatively larger tubes in the 2.5 – 10 cm (1 – 4 inch) range. As a result, more active catalysts can be used.

Microchannel FT reactors (marketed under the brand name Velocys) and a highly active FT catalyst have been successfully tested at the laboratory, pilot and demonstration scales. A further field demonstration incorporating the microchannel FT technology is expected to be qualified during the second half of 2013.

Oxford Catalysts Group / Velocys

Oxford Catalysts Group PLC is changing its name to Velocys plc on 25th September 2013.

The Oxford Catalysts Group develops and commercialises microchannel reactors and process technology for the conversion of unconventional, remote and problem gas into valuable, clean-burning liquid fuels. It owns, or has exclusive licence to the largest microchannel patent portfolio in the world, encompassing more than 800 patents with more than 25,000 patent claims across the globe. The company has in-house catalyst development and microchannel development teams. Applications for its technology include gas to liquids (GTL), biomass to liquids (BTL) and coal to liquids (CTL).

Systems based on the Group’s technology (marketed under the brand name Velocys) are significantly smaller than those using conventional technology. This enables the building of modular plants that can be deployed cost effectively in remote locations and on smaller fields than is possible with competing systems.

Oxford Catalysts Group PLC is listed on the AIM market of the London Stock Exchange (LSE: OCG). The Group has 90 employees with facilities near Oxford, UK and Columbus, Ohio, USA.

www.oxfordcatalysts.com

www.velocys.com

The International Gas Technology Conference (IGCT)

The IGTC is one of three conferences taking place between 16-20 September as part of Moscow Refining, Gas & Petrochemicals Week in Russia. The event, organised by Euro Petroleum Consultants and now in its 12th year, is supported by the Association of Russian Refiners and Petrochemical Producers, and claims to be the largest and best established technology event dedicated to the downstream industry.