Vaal University of Technology head of the Innovation Centre Jan Jooste has developed a new configuration of the vertical axis wind turbine, which he stated could realise a shift in wind energy generation from horizontal axis wind turbines, as well as sign

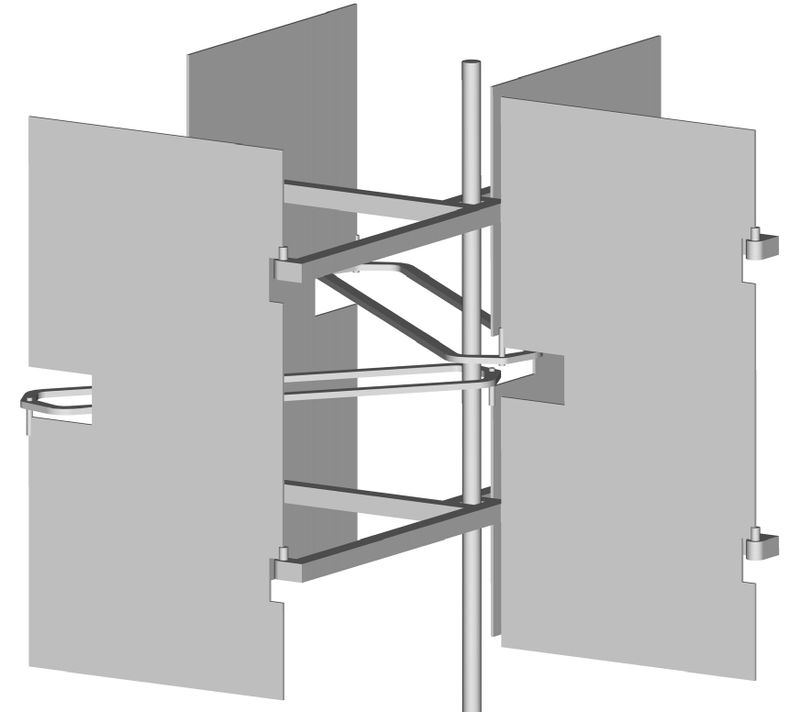

Still in the testing phase, Jooste’s configuration of the vertical axis wind turbine consists of three blades over three levels, as opposed to the single layer used in a conventional vertical turbine.

Following wind tunnel testing results, Jooste added that the new configuration increases energy yield by 400%. This, he said, was because the two additional layers increase the area of energy capture by 200%, and, as the energy yield correlates with the area – the energy yield will similarly increase by a further 200%.

“Initial results, as well as theory, support a 400% improvement in energy harvesting, relative to the conventional configuration of vertical axis wind turbines,” said Jooste.

He said that a further benefit of the new configuration was that blades were now continuously spinning through fresh wind with higher energy levels. “In conventional vertical axis wind turbines, the blades spin through fresh wind in the upwind half of their rotation – but pass through reduced energy wind in the downwind half of the rotation. The impact of this improved downwind half, seems to be an overall increase of about 200% in energy yield.”

He explained that this could realize a shift from the more popular horizontal axis wind turbines, towards vertical axis wind turbines. “This shift would also be supported by the fact that vertical turbine blades are much easier to manufacture than horizontal axis blades, and blade manufacture could also be automated,” Jooste noted.

He highlighted that a further change could occur in the entire energy generation industry.

“It would upset the approximate parity in generation costs per unit of energy, between wind and coal. About 70% of the generation cost for wind energy serves to recover capital cost. If capital cost could now be reduced by 60%, the generation cost per unit of energy would drop by 42%, which would make alternative generation the rational choice, even in the absence of subsidies,” Jooste reiterated.

SCALING UP

“We have outgrown our wind tunnel. Next scale tests will involves driving a truck along an airfield runway at various speeds, to spin two turbines (conventional and high performance) mounted in a frame at the front. Everything will be instrumented to measure the speed of incoming air as well as the turbine rotation and power output,” said Jooste.

It was expected that the measured 400% increase could decrease to about 300% at larger scale tests. Current tests were not conducted under conditions that generate high confidence, however, larger scale tests would be more reliable.

Discussion with various potential funders was under way, although Vaal University of Technology would likely fund the next phase of research. “Economic conditions necessitate that a number of funders be approached,” noted Jooste.

A holding company for the technology, Enerqi Technologies, has been created, and intends to license the technology to manufacturers at an affordable fee per kilowatt of capacity sold.

“Enerqi Technologies will not become a manufacturer, primarily as we cannot be both a player and a technology provider in the market. Furthermore, the market is just too big for a new player to make an impact,” said Jooste.

He added that with a market of this size, and showing growth, it was competitive, and would not be easy to collect royalties from such players, however, he said that the prospect of a sustainable competitive advantage would make the business case.

“We should prove the technology as soon as possible and climb the learning curve. High performance turbine power could reach 1 MW in five years and should later reach the 2 MW to 5 MW capacity of current big horizontal axis wind turbines,”

In terms of energy generation, Jooste said: “We will be doing well to have a 100 kW turbine running in two years time. Such a turbine will have a diameter of 9 m, blade length of 8,33 m, chord of 0,75 m. Total blade height will then be 25 m, and it will generate 100 kW over the 225 m2 swept area in a 12 m/s wind to attain a coefficient of performance of 42%.”

“We should prove the technology as soon as possible and climb the learning curve. High performance turbine power could reach 1 MW in five years and should later reach the 2 MW to 5 MW capacity of current big horizontal axis wind turbines,” said Jooste.

Although not often seen in South Africa, Jooste noted that vertical axis wind turbines are used in Europe and the US for urban electricity generation, but are no longer used for utility scale electricity generation in the US and Canada, where they were used from 1970 to 1990.

Vertical axis wind turbines have vertical blades spinning around a vertical axis, where-as the more common horizontal axis wind turbines, as found in Darling, in the Western Cape, and across Europe, have three blades spin around a horizontal axis.

Among the advantages of the vertical arrangement are that generators and gearboxes can be placed close to the ground, and that they do not need to be pointed into the wind.