Plasma gasification melting (PGM) technology that transforms municipal solid waste (MSW) into synthesis gas and products suitable for construction materials

The core of Environmental Energy Resources Ltd.’s technology was developed at the Kurchatov Institute in Russia, according to Liran Dor, chief technology officer and technical director, and has been used for more than a decade for the treatment of low- and intermediate-level radioactive waste in Russia. It is also applicable to MSW, municipal effluent sludge, industrial waste and medical waste.

Describing how the PGM system works, Dor said first the waste is fed into a vertical shaft vessel through an airtight feeding chamber at the upper portion of the system, and moves downward to pass through a drying zone where moisture in the waste is evaporated. The putrescible (decomposable) organics are converted into a pyrolysis gas, which forms a synthesis gas along with the gasification products, and is then evacuated from the vessel.

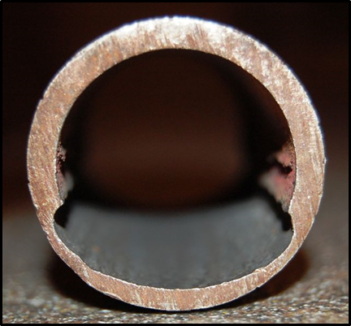

Oxidizing agents are then introduced to gasify the carbonic residues of the pyrolysis, producing carbon monoxide and hydrogen, which join the pyrolytic gases to increase calorific value. At the bottom of the vessel, plasma torches form an electric arc which ionizes air flowing through the torch to form a plasma jet, which may reach up to 4,000 degrees Celsius (7,232 degrees Fahrenheit). The plasma jet melts the inorganic fraction of the wastes to form an inert vitrified slag that can be used in construction materials or as roadbed aggregate.

The syngas can be combusted directly in a gas turbine to provide required power for the facility, and excess electricity can be sold to the grid or for other users. In a combined-cycle arrangement, the system has an electrical efficiency of about 40 percent to 45 percent, according to Dor. In terms of volume, approximately 1,000 cubic meters of syngas are generated in the PGM from 1 ton of MSW. PGM facilities produce up to 70 percent lower volume of gas to be cleaned, as compared with incineration.

“The process generates very little toxic fly ash, compared with 2 [percent] to 5 percent by weight in incineration of MSW,” Dor said. “The PGM also has the additional capability of feeding the fly ash back into the vessel.”

EER has operated a demonstration facility in Yblin, Israel, since late 2006 where it processes 12 to 20 tons of MSW per day. The company also has a 20-year agreement with Gowing & Pursey, a London-based waste management company, to construct a PGM plant in the U.K. According to the agreement, EER will supply the technology to construct and operate the plant, which will have a 30,000 ton per year capacity. G&P will supply the MSW.

Additionally, EER is currently in the permitting stage for the construction of a medical waste processing plant in Houston, Texas.