2G – CENERGY received an order for a biogas cogeneration plant to be constructed in the State of Washington.

The 400 kWh CHP system will be installed in Lynden, WA, about 95 miles north of Seattle. It is scheduled to be installed in late 2010. Lynden-based DARITECH Inc. will build the anaerobic digester, and the Van Dyk Dairy Farm owns and operates the biogas plant.

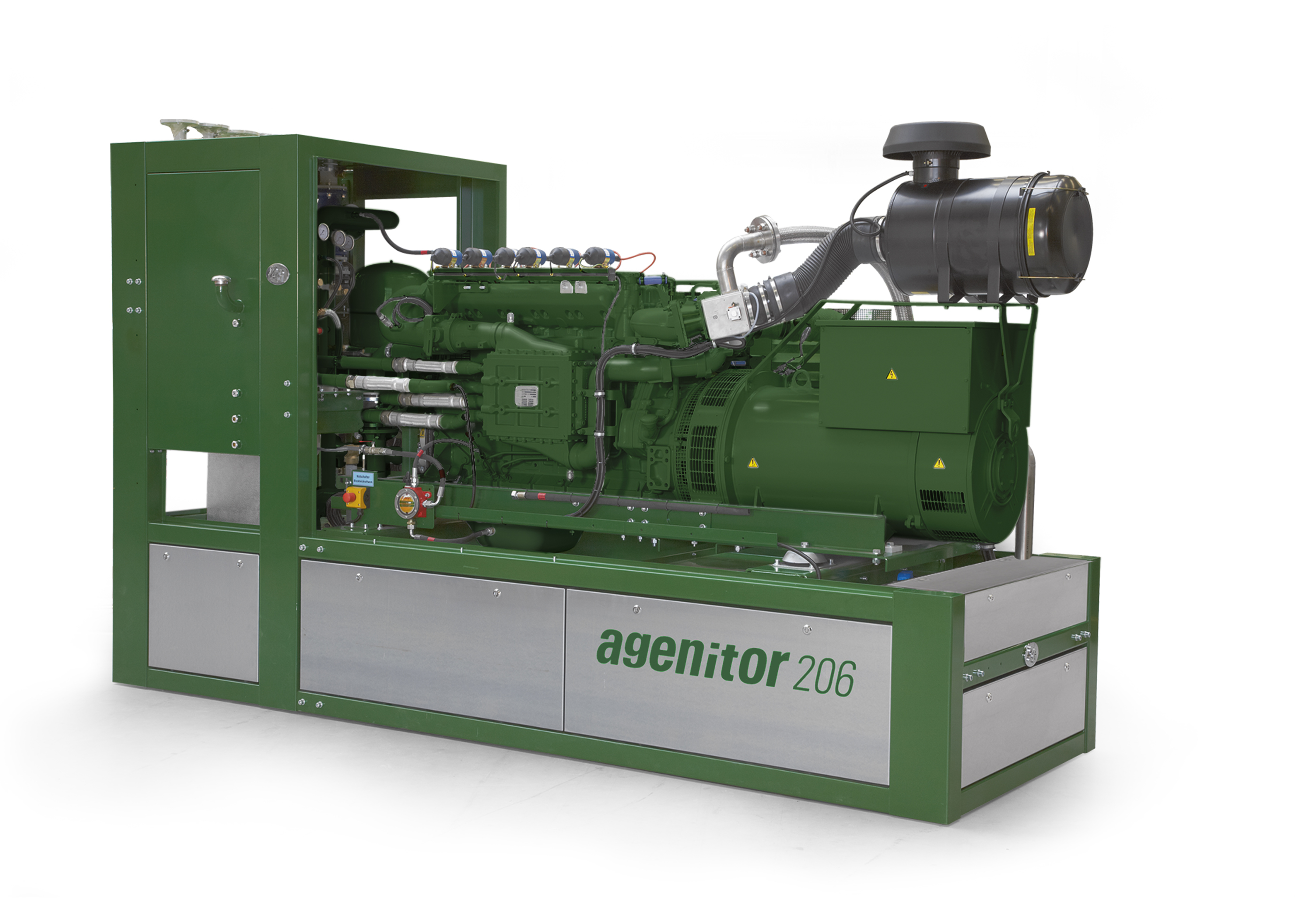

The plant is expected to produce 4706 MW of thermal energy and 3320 MW of electricity per year, with any excess power sold to the grid. The combined heat and power plant uses the 2G® agenitor®, a thermodynamically optimized MAN® cogeneration gas engine coupled with the patented 2G-Drive® technology, especially developed for biogas operations. Benefits over conventional MAN®, or any other gas engine, include much higher efficiencies, extended life, and less maintenance cost.

2G®’s output-optimized cogeneration CHP (combined heat and power) modules have been installed at more than 1200 biogas plants around the world.

“The increased degree of electrical efficiency is crucial for successful biogas plant operations. At the end of the day, every additional percent of increased efficiency makes a huge contribution to the overall project bottom line, resulting in more profitability and a much better economy for the system operator”,… says Michael Turwitt, President & CEO of 2GCENERGY

Power Systems Technologies Inc.

Being extremely successful in Europe for many years, manure-powered biogas facilities are becoming increasingly popular in the USA. The combined heat and power (CHP) plant — the first thermodynamically optimized biogas cogeneration plant of this kind in the State of Washington — has enough capacity to power 373 homes. “According to the Department of Energy, the average household in the US uses about 8,900kW of electricity each year. Even small dairy farms have the ability to juice up hundreds of homes”,… explained Michael Turwitt.

The advantages of using biogas power are threefold: The dairy farm improves its energy efficiency, cuts down on greenhouse gas emissions, and keeps manure out of the waste stream. After manure goes through the biogas plant, residues can be used as agricultural fertilizer.

Besides being more efficient, 2G® cogeneration systems with low-emission generation capability are designed and manufactured “connection ready”. All plants are fully factory tested and come as complete modules. This allows for extreme fast and cost-effective installation, increases product reliability, and assures trouble-free operations.

About 2G – CENERGY Power Systems Technologies Inc.

Headquartered in Orange Park, FL, 2G – CENERGY Power Systems Technologies Inc. is a US Corporation owned by 2G Bio-Energy Technology Corporation (2G Bio-energietechnik AG) Germany, MAGNA Venture Capital & Investment, LLC, United States, and CENERGY’s senior management team. 2G is a longestablished company publically traded at the Frankfurt Stock Exchange. 2G Bio-Energietechnik AG is one of Germany’s leading manufacturers of combined heat and power (CHP) systems, with more than 1200 cogeneration plants installed. The company’s CHP power plants guarantee extreme high energy efficiency, extracted and generated from biogas, landfill gas, sewage gas, coal mine gas, natural gas, syngas and biofuels. 2G-CENERGY provides technologically advanced and clean systems to generate electricity and heat, while reducing CO2 emissions and greenhouse gases. All plants are designed and manufactured “connection-ready”.

Source: 2g-Cenergy