While the biogas market in Europe is well-developed, it has taken longer for the industry to gain a foothold in North America.

Cogeneration is the environmentally-friendly, economically-sensible way to produce power, simultaneously saving significant amounts of money and also dramatically reducing total greenhouse gas emissions. 2G’s concept of smaller modular combined heat and power plants for decentralized energy production, especially biogas and natural gas fueled, is leading the way in North America.

While the biogas market in Europe is well-developed, it has taken longer for the industry to gain a foothold in North America. However, the number of decentralized power plants is increasing, and new biogas project announcements suggest the U.S. is finally ready to catch up with other industrialized markets.

In January 2010, 2G-CENERGY Power Systems Technologies Inc., a U.S.-based manufacturer of highefficiency biogas-and natural gas energy conversion systems, jointly owned by 2G Bio-Energy Technologies in Germany (2G Bio-Energietechnik AG, publically traded at the Frankfurt stock exchange), and its North American management, announced the company plans to focus largely on the developing biogas market in the United States.

“We’ve been the market leader in Europe for many years but really saw a great growth opportunity in North America,” said Michael Turwitt, 2G-CENERGY president and chief executive officer. The company uses a modular CHP and cogeneration technology that converts biogas and other gaseous fuels into valuable electrical as well as thermal energy. The result is a renewable energy production, environmentally friendly, very economical, and dramatically reducing greenhouse gas emissions. The technology is applied in combination with all types of anaerobic digesters (agricultural and organic waste streams), at landfills, and in combination with methane generating waste water treatment facilities.

To date, 2G’s technology has been utilized in more than 1500 biogas projects in Europe, and many other locations in various industrialized countries. In North America the company successfully commissioned plants in Washington State, Wisconsin, Ontario, and is in the process of installing its advanced modular CHP technologies in Massachusetts, New York, South Carolina, Texas, and in Mississippi. Additional projects are forthcoming in Oregon, California, Pennsylvania, and in Ohio.

Most recently in Mississippi, Three Rivers Solid Waste Management Authority located in Pontotoc decided to purchase a modern 2G biogas power plant, a 1.3 million $ investment, for their landfill facility.

In April EMG in Pennsylvania awarded 2G-CENERGY with an order to supply a high efficiency biogas CHP (combined heat and power) cogeneration plant for EMG’s anaerobic fluidized-bed digester technology to be installed at a large brewery in New York.

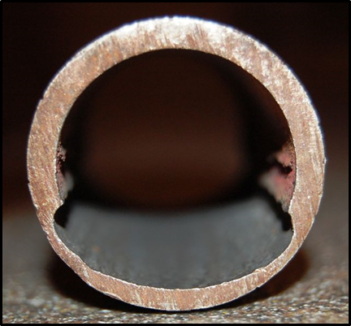

Instead of the conventional design-build, or site-build process, 2G customers always decide for a 100% modular “all-in-one” and “connection-ready” cogeneration system to save cost and to reduce technical risk. The cogeneration process results in overall electrical and thermal efficiencies close to 90%, compared to most utility power plants operating in the 33% percent efficiency range. 2G’s systems are an integrated package, fully containerized and are supplied as a unique “all-in-one” and “connection-ready” modules. Benefits over conventional gas engine gensets (often wrongly compared with CHP systems) include much higher overall efficiency, reliability, durability, extended life, fast installation, and less maintenance cost.