Continental Wind Power was to make a difference by lowering fossil fuel consumption and reducing CO2 emissions

When it was founded in April 2007, the aim of Continental Wind Power was to make a difference by lowering fossil fuel consumption and reducing CO2 emissions through expanding the market for clean wind energy. The company founders realized that as newcomers they couldn’t compete with the likes of GE, Clipper, Siemens and Vestas, companies that were well established as the makers of massive multi-megawatt turbines designed to pump electricity into the general grid.

What Continental needed was a niche that wasn’t being filled by these large companies. Through a series of introductions, good fortune and proper timing, Continental discovered that there was a specialized market niche, a group of customers, whose needs fit between the gigantic multi-megawatt wind turbines and the backyard varieties and whose needs weren’t being served. The company identified a market for medium sized wind turbines – those in the 300-900 kilowatt range.

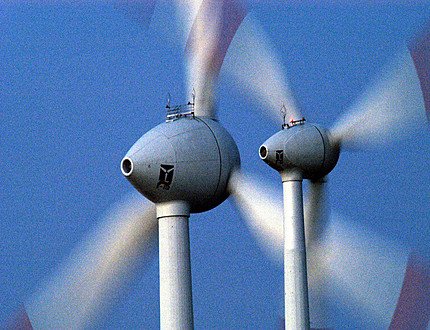

Continental decided to design and build medium sized turbines that would be ideal for large power consumers. Many large power consumers have a strategy in place to replace a portion of their consumption with local wind power. The large power users Continental was talking to had their own land located on sites rich in wind resources. The company designed wind farms that would typically consist of five to 25 wind turbines that will supply power to the factory complexes, schools, cities, counties, wastewater treatment plants, water pumping facilities, small, medium and large farms, as well as for developers seeking to provide clean energy for their residential and commercial projects. Generally located in larger population or industrial centers, distributed wind farms are more efficient because they generate power closer to where it is needed in greater quantity.

Although the company is keeping most of its technical details under wraps, according to CEO Jim Winsayer the turbines will be less than 200 feet tall and generate about 300 kilowatts of electricity. One turbine would supply enough electricity for roughly 100 homes.

As the customer pipeline filled up, Continental received an angel investment to help move them forward. Continental has already-booked sales that are in the eight-digit range and as a result is currently seeking a Series B funding for the establishment of its U.S. wind turbine manufacturing and development center in Santa Paula, California.

The discovery of the untapped medium sized turbine market was timely, but it presented certain challenges. For example, orders for blades, gear boxes and other components have backed up at existing vendors. Wait times for component equipment have been as long as three years. (Also competing in the small to medium size wind turbine market is Germany’s Enercon. )

Continental had to start from scratch and has spent the last year and a half designing its turbines. With the completed design plans in hand, the company sent out requests for proposals to potential subcontractors. They have been looking for everything: blades, generators, gear boxes, ladders, control boards, software and other equipment.

Continental’s solution to the pinched supply line was to target vendors that weren’t making turbine components, but could be. For example, a mobile-communications tower company could build the wind-measuring towers that determine the suitability of a turbine site, even though the communications company has never done so before. By taking a chance on a vendor new to turbines, Continental circumnavigated pinch points in the supply chain and the vendors were invited to enter a lucrative new space.

In June Continental announced plans to build a wind power facility in Santa Paula, California that will produce the medium sized wind turbines. They will operate in much smaller installations compared to the larger wind turbines made by most other manufacturers today. The new Santa Paula wind turbine plant could eventually produce 600 turbines a year. Continental Wind Power will begin production of wind turbines in 2010 that are slated for installation at wind farms beginning at the end of 2010.

Continental is also attempting to maximize impact in stimulating the American economy by attempting to source everything in the U.S., and the company is prioritizing purchasing from local component manufacturers. “There’s actually a pretty good concentration of firms, particularly in Ventura County, that may be hurting because of offshoring. Now there’s an opportunity to bring some of this business back here,” said Winsayer.

The company will start hiring soon, which could bring 300 to 500 green collar jobs to Santa Paula for positions ranging from assembly workers to industrial engineers.