Produces highly reflective ‘Vega energy’ aluminium mirror layers used in solar thermal plants

Munich (Germany),

Almeco-TiNOX is concentrating its production and R&D activities for its highly selective ‘TiNOX energy’ absorbers for flat-plate and evacuated-tube collectors at its facility in Bernburg, Saxony-Anhalt. The company has already been operating one of the world’s most advanced PVD vacuum-coating systems here since 2008. In addition to absorbers, the German-Italian company also produces highly reflective ‘Vega energy’ aluminium mirror layers used in solar thermal plants and process heat facilities to generate electricity, heat and cooling.

Customers stand to benefit from centralising these activities, as all steps in the production process are now carried out under one roof. This enables Almeco-TiNOX to process orders faster and more efficiently. For example, the company can quickly produce custom sizes on its high-performance longitudinal cutting station in Bernburg. Almeco-TiNOX plans to install an additional sheet-cutting machine in Bernburg in order to offer its customers even more service.

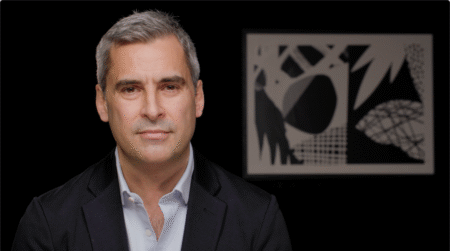

“It wasn’t an easy decision for us to shift production from Munich to our facility in Saxony-Anhalt, especially given the fact that Munich is the birthplace of our highly selective absorber. We invented this technology here on the Isar. Since that time, TiNOX has been synonymous with highly selective absorbers in the solar thermal sector,” confirms Almeco-TiNOX’s CEO Georg Kolmeder. “However, we decided to concentrate production and R&D operations in Bernburg because it enables us to deliver our products even more quickly, reliably and individually to our customers.”

The transfer of these activities from Munich to Bernburg has already been completed and the systems are up and running. Sales, marketing and administrative operations remain in Munich.

About Almeco-TiNOX GmbH

Almeco-TiNOX specializes in high-tech coatings that convert sunlight into heat energy – in an efficient, reliable, and environmentally friendly manner.

The highly selective “TiNOX energy” absorbers for flat-plate and evacuated tube collectors are one such technology. The company can help manufacturers of solar thermal collectors reach excellent performance with the latest high-volume production systems based on many years of experience and comprehensive expertise in the coating of copper and aluminum sheets.

In addition, Almeco-TiNOX’s “Vega energy” product line consists of efficient solar mirror coatings for evacuated tube collectors, process heat applications, and concentrating solar power plants, which increases the heat yield of such systems considerably. “Vega energy” customers benefited from Almeco’s many years of experience in the production of highly reflective aluminum coatings for lighting applications.

Almeco-TiNOX is also a competent, committed service partner for its customers. For instance, the company is known for its fast, reliable delivery, its dense international distribution and service network, its wide range of special services, and — last but not least — its comprehensive individual technical consulting services.

More information is available from: www.almeco-tinox.com.